Te2. Our first turntable.

Inner Beauty

Turntables are back with a vengeance, but time doesn’t stand still. Technology’s pace allows us to revisit problems and solutions of the past with new eyes and new means.

We looked at one of the older and most cherished drive systems – idler drives – and proceeded to iron out its kinks and foibles with modern technology and materials. The result surprised us and will surprise you.

Starting with the drive system, motion is supplied by a BLDC motor, epicyclically driving the aluminum platter through an urethane drive wheel. The motor is attached to a telescopic cradle using sorbothane rings for vibration decoupling.

The platter, of medium weight (3.4Kg), is constructed from aluminium with the major mass around its circumference for a greater Moment of Inertia. Its underside is covered in butyl rubber to quell any “ringing”. It is held in place by an inverted bearing with a 16mm shaft, its weight supported by twin ceramic spheres.

Everything ties together at an stainless steel cross-frame, for rigidity and precision. The frame itself attaches onto a MDF and acrylic multi-layered plinth. At the plinth, all other parts – armboard, enclosure, power and control electronics – are bolted to, on precision located mounting points.

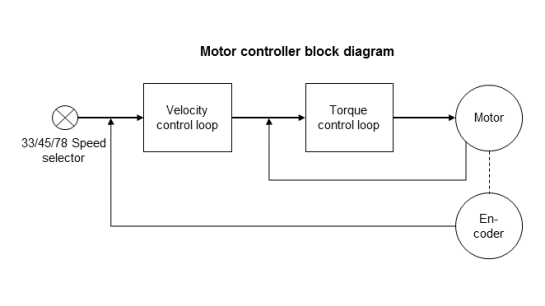

The inboard power supply, line filters the mains supply before converting it to DC and stabilizing it. It then feeds the motor controller, which features electronic speed switching (33/45/78), along with quick start and quick stop characteristics.

The correct speed is constantly monitored and accurately maintained thanks to a sophisticated PID controlled sine wave generator, fed by a 1000-step optical encoder.

This ensures that the right amount of torque is always provided – i.e. the absolute minimum required – based on the current levels demanded by the motor.

Outside, everything is bliss and calm

Complexity is hidden, or rather function doesn’t dictates form. We strived for a classical, contained appearance, able to subtly fit into any decor and not scream about itself. Alcantara fabric frames the turntable, while the top is covered in brushed aluminium or stainless steel.

Arm / Cartridge combination

Our standard combination includes an Origin Live Silver tonearm and either an Audio-Technica VM750 (MM) or a Jico Seto-Hori (MC) cartridges. However, adapters for other tonearms can be supplied instead, at no additional charge.

Colors, you ask ?

For a small additional cost, instead of black, we can finish our turntable in any available colour from Alcantara’s extensive palette.

Optional Dust Cover

For protection from dust – and little fingers – an optional dust cover is also available.

Specifications

- Epicyclic drive

- BLDC motor with digital, relaxed closed-loop PID control system

- 33 / 45 / 78 rpm capability (78 with pitch control in 0.5% steps)

- Twin ceramic inverted bearing design

- Chrome-plated, induction hardened 16mm platter shaft

- Constrained layer MDF plinth construction

- Stainless steel cross-frame chassis

- Supports tonearms between 9”-12”

- Aluminium + rubber damped platter construction

- Height adjustable damped feet (4)

- Exterior finished in Alcantara and brushed Aluminium / Stainless steel

- Platter / Total weight: 3.5Kg / 17Kg

- Dimensions (without tonearm and feet): 52(w) x 41(d) x 12(h) cm

Performance

Although, we don’t believe that numbers are the only game in town, we do measure them, which is not very common today. Wow & Flutter, along with Rumble have been the most common measures used to evaluate turntables ever since, but we know there’s more to sound than just those two.

In fact, those two can be misleading: W&F is an average, scarcely revealing the magnitude and frequency of the ocurring speed drifts; Rumble is also mostly useless, as today, the backgound noise from the records usually surpasses the noise coming from the motor / bearing.

However, at least for a ballpark / baseline perspective, we do measure them. Below, the plots from a recent W&F test can be seen. We used the Ios PlatterSpeed app along with Dr. Feickert’s 7″ test record and a 40sec sample. And they made us proud !